| MGF Cars: Left Hand Drive (LHD) Conversion |

As a result of informal customer focus groups and notwithstanding the discriminatory & highly prejudicial attitudes of various government agencies and insurance cartels across Canada towards right hand drive (RHD) vehicles, we have decided to make our left hand drive (LHD) conversion programme for the MGF a high priority.

Fortunately, and somewhat surprisingly since export to North America was apparently ruled out relatively early in the project, MG Rover designed the MGF so that variances in drive side would require minimal component changes compared to most other cars.

Clearly, the dashboard and steering rack will require replacement, but there are also implications for the pedal box, windscreen wipers and last but not least the wiring harness.

The location of some components such as the handbrake lever remain the same regardless of drive side, but the brake master cylinder & booster are on the opposite side of the steering wheel. We have recently learned this was done for crash protection purposes.

For a perfect conversion down to the last detail one must not forget items such as the keyhole in the former passenger side outer door handle and the wear pad on the drivers side carpet! |

|

|

With the dashboard removed the project is now well underway! |

|

This is the plate that supports the clutch master cylinder and wiper motor. This part can be located on either side as required. |

|

With the brake booster, wiper mechanism and fresh intake removed, the next step is to replace the cross shaft brackets with LHD parts. The bar itself could be reused but the brackets are handed. |

|

Clearly, the pedal configuration is quite different depending upon drive side, but the mounting points are the same. |

|

This reveals how the factory went to great lengths to make this conversion 100% bolt-in. This blanking plate is simply moved to the other side. Even the sound padding appears to have cutouts! We have trial fitted the column support bracket in this photo and one wonders why the factory left it bare metal even inside the car! |

|

Simply remove this grommet to make way for the brake pedal pushrod. Thank you MG for making such a great car and making our job of changing some of the cars from Britain to suit North American road conditions relatively easy all these years later! |

|

This part does not appear to be handed, and aside from being a bugger to remove when the captive nuts strip out and the ones on the bottom rust, from the shape it appears that it is more suited to LHD applications! |

|

After wire brushing the rust from this bracket a coat of clear rust paint will be applied in the interests of originality, yet with the goal of keeping surface rust from returning. |

|

Perhaps the most time consuming aspect of the conversion is replacing the wiring harness. |

|

We decided to go with a new heater box assembly as we have managed to acquire enough to cover a handful of conversions. After that it will be a question of adapting the existing part unless we can find a continuing source of supply. |

|

With the heater box out we are about to turn the corner on the conversion............... |

|

............ and voilà! The bulkhead insulation pad is turned around to the new LHD position. There is only one part number for this padding and yet again MG Rover has made our job easier! |

|

The steering rack and cross tube assembly are different for LHD and here they are shown with their RHD counterparts. |

|

Starting to go back together. Of course the brake & clutch pipes will need to be replaced and/or shortened & re-flared. |

|

Inside the car we have re-fitted the pedal box assembly and the new fuse box bracket. |

|

Initial harness placement looks like a mess but stay tuned! |

|

Perhaps the most obvious part that needs replacement! |

|

The upper part of the steering column can be reused but........ |

|

....... the lower part must be replaced. The service manual talks about paint markings, but in case these are no longer present here is a comparison. |

|

Now that looks a bit better eh? Notice the relocated fuse box & EPAS control unit. |

|

With the dashboard fitted the conversion is moving right along. |

|

Followed by the instrument cluster and steering wheel. |

|

The part on the left could end up being our first MGF remanufacturing projetc. These steering column hole covers are very hard to come by for LHD.. |

|

Awaiting new LHD carpets amongst other items. |

|

Since the fusebox is now on the left of the ignition switch it is necessary to make up a short link lead if not replacing the ignition switch. |

|

The master cylinder has now been relocated with new brake lines. |

|

All that remains is the reinstallation of various trim pieces. The car started at the turn of the key. |

|

The MGF uses a very unusual brake reservoir. We are hoping to work with Motive Products on a custom MGF reservoir adapter that will allow the use of their excellent one person brake bleeding system. Stay tuned! |

|

A new LHD under bonnet finisher makes everything look tidy again. We are just waiting on a set of LHD wiper arms and the missing horn! We were able to re-route both the speedometer cable and the brake vacuum pipe for the time being as the correct LHD versions of these components are not easy to obtain. |

|

Awaiting a LHD instrument panel finisher and re-installation of the column nacelles. Drove the car about five miles and other than needing an alignment all appears well! |

|

Another somewhat elusive part. This underside view shows why it cannot just be swapped from side to side despite the column cutouts being in the same position. Fortunately it is something our plastics people can reproduce, for a price, if demand for conversions is great enough! |

|

Remaining trim installed. The console panel is adrift as we are still diagnosing a non operational oil temp. gauge issue. |

|

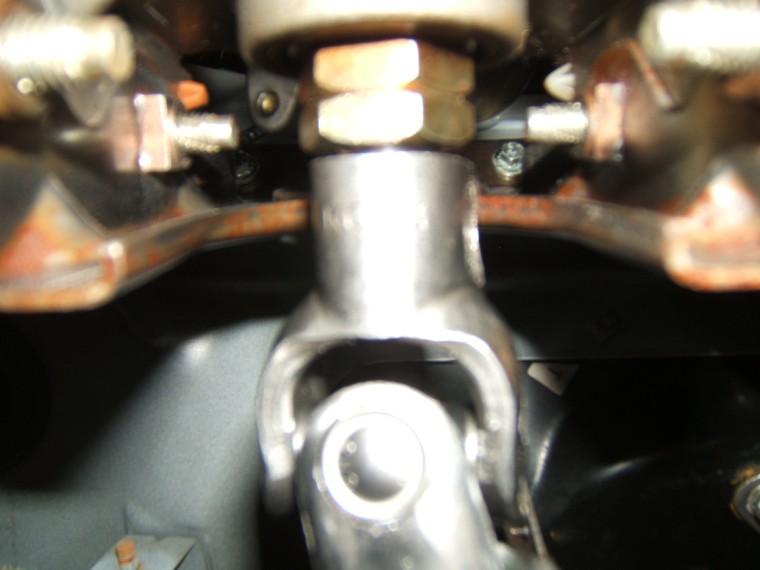

This photo shows the upper joint connection on the RHD car. The pinch bolt is horizontal and of course this position is fixed in relation to the lower joint. |

|

This photo shows the lower steering column connection at the rack of a RHD car with the road wheels in the straight ahead position. |

|

This photo shows the lower connection on the car just converted to LHD. Should the head of the pinch bolt be pointing straight down as on the RHD car? |

|

The upper joint of the LHD converted car. If the lower yoke in the photo to the left is changed to match the RHD car the pinch bolt here will then be 180 deg opposite to the RHD car as it should be? The service manual is totally lacking any information on this topic. |

|

There is a notch on the rack pinion shaft meaning the lower joint can only go on one way. Therefore we turned the wheels ever so slightly to line up the lower joint as above, thus an adjustment will now need to be made at the tie rods. |

|

With the lower joint aligned the upper joint is now 180 deg. opposite to the RHD car which makes sense considering the comparison photo of the two shafts above. |

|

A comparison of the wiper arm configurations for LHD and RHD. |

|

LHD wiper arms installed. |

|

For a perfect conversion, the door handles must be swapped as only the drivers side has a lock cylinder. |

|

A comparison of the back side of the old and new handles. |

|

Fortunately, the lock cylinder can be swapped to the other side with minor modification as a new latch will come with a new lock rod. |

|

The old RHD latches shown with the new LH side latch. These are tied into the central locking system so need to be changed to ensure correct functioning of the central locking system. |

|

|

The biggest long term challenge to this project will be sourcing components as there are a finite number of LHD MGF's in scrapyards (as it should be, we hate to see a car scrapped). Thus, if demand for the car proves sufficient in Canada we will resource the necessary components to perform this conversion. Such an undertaking will require volume, however. Even a die to stamp the aforementioned cross tube bracket costs hundreds of Dollars.

|